Ducts

Our Products/Ducts

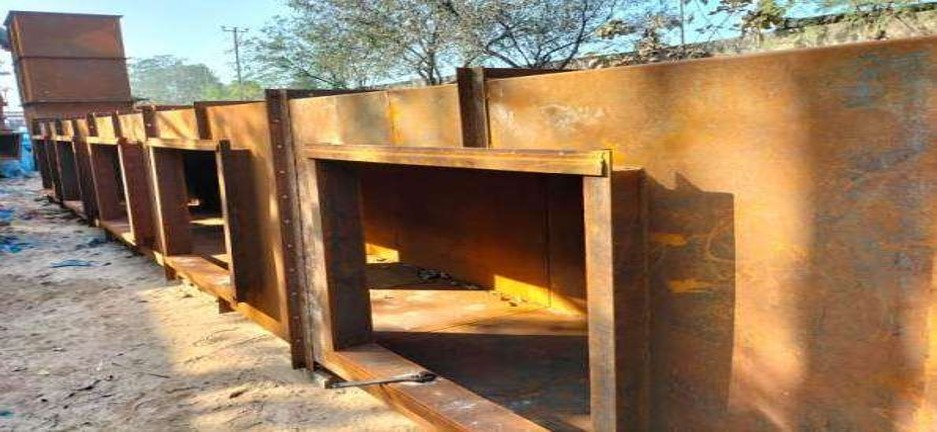

CONV. PRE HEATER DUCTING, manufactured and supplied by Goel Industries, is a specialized system designed to transport hot gases or air in a controlled manner as part of pre-heating processes. Commonly used in industries like power generation, cement production, and steel manufacturing, it enhances energy efficiency and optimizes thermal operations. Its primary functions include managing gas flow between plant sections, recovering residual heat to pre-heat raw materials, maintaining the appropriate temperature for pre-heating, and reducing energy costs by efficiently utilizing waste heat.

On Client's Demand Ducts & Assy Structure

JSW RANIHATI

TATA STEEL KALINGANAGAR

JSW RANIHATI

TATA STEEL KALINGANAGAR

.JSW RANIHATI

JINDAL INDIA LTD RANIHATI

CMI EPE